An unformed stamper is the result of the electroforming process after either of the technologies (DMM or lacquer) implemented. After the stamper is produced, it is necessary to prepare it for the pressing machines. The stampers still need to be formed and trimmed in order to fit the pressing moulds on the record pressing machines.

Polishing

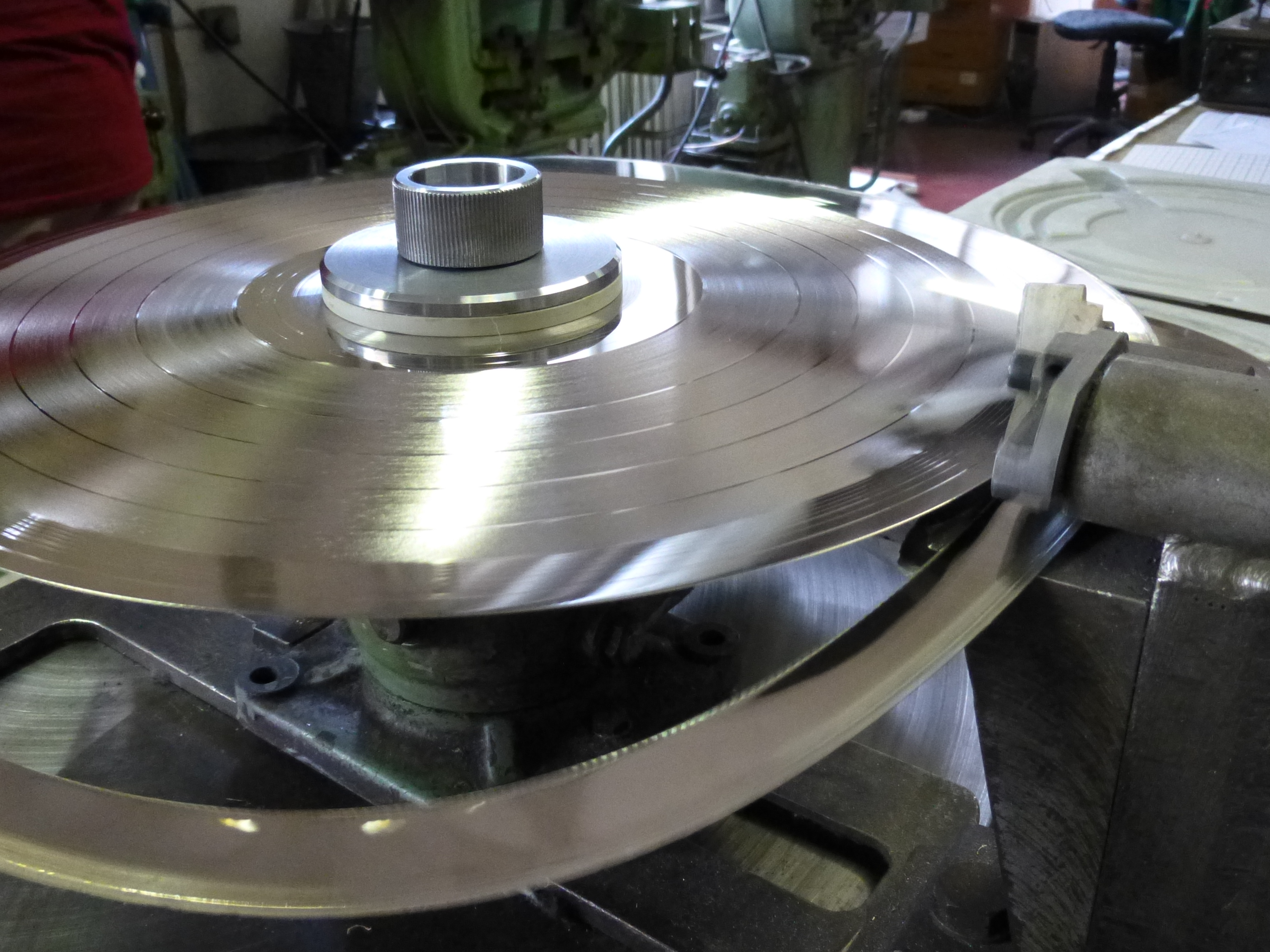

The back side of the stamper must be absolutely flat and smooth – free of any imperfections which would affect the quality of the press. The stamper is placed on a special rotating wheel device and manually hand sanded with different grades (from a coarse to a fine) of abrasive sandpaper which finely polishes the back surface of the stamper. A soft velvet pad is applied to the front side of the stamper to avoid damaging the grooved surface.

The back side of the stamper must be absolutely flat and smooth – free of any imperfections which would affect the quality of the press. The stamper is placed on a special rotating wheel device and manually hand sanded with different grades (from a coarse to a fine) of abrasive sandpaper which finely polishes the back surface of the stamper. A soft velvet pad is applied to the front side of the stamper to avoid damaging the grooved surface.

Centering

Vinyl records will show even the smallest eccentricity during playback. The physical centre of the record, for example, should also be the exact centre of the spiral groove containing the sound. It is therefore necessary that the central hole of the stamper is absolutely accurate. During the centring process, the stamper is placed in the centre of a rotating wheel device and magnetically clamped with set screws. The magnified image of the stamper’s grooves is then viewed on a screen via a microscope. During the rotation, the operator manually corrects the position of the stamper by means of the screws so that the groove is centred within the tolerance field. Once the stamper is in the correct position, the machine creates a central hole according to the required dimension.

Vinyl records will show even the smallest eccentricity during playback. The physical centre of the record, for example, should also be the exact centre of the spiral groove containing the sound. It is therefore necessary that the central hole of the stamper is absolutely accurate. During the centring process, the stamper is placed in the centre of a rotating wheel device and magnetically clamped with set screws. The magnified image of the stamper’s grooves is then viewed on a screen via a microscope. During the rotation, the operator manually corrects the position of the stamper by means of the screws so that the groove is centred within the tolerance field. Once the stamper is in the correct position, the machine creates a central hole according to the required dimension.

Trimming

The edges of the stamper must be trimmed in order to fit the required diameter of the final size of the record – which can be different from format to format. The stamper is affixed to a trimming machine consisting of a rotary disc with a cutting blade, and is cut to the template dimensions of 320mm, 265mm or 192mm. The sharp edges of the stamper are then manually polished.

The edges of the stamper must be trimmed in order to fit the required diameter of the final size of the record – which can be different from format to format. The stamper is affixed to a trimming machine consisting of a rotary disc with a cutting blade, and is cut to the template dimensions of 320mm, 265mm or 192mm. The sharp edges of the stamper are then manually polished.

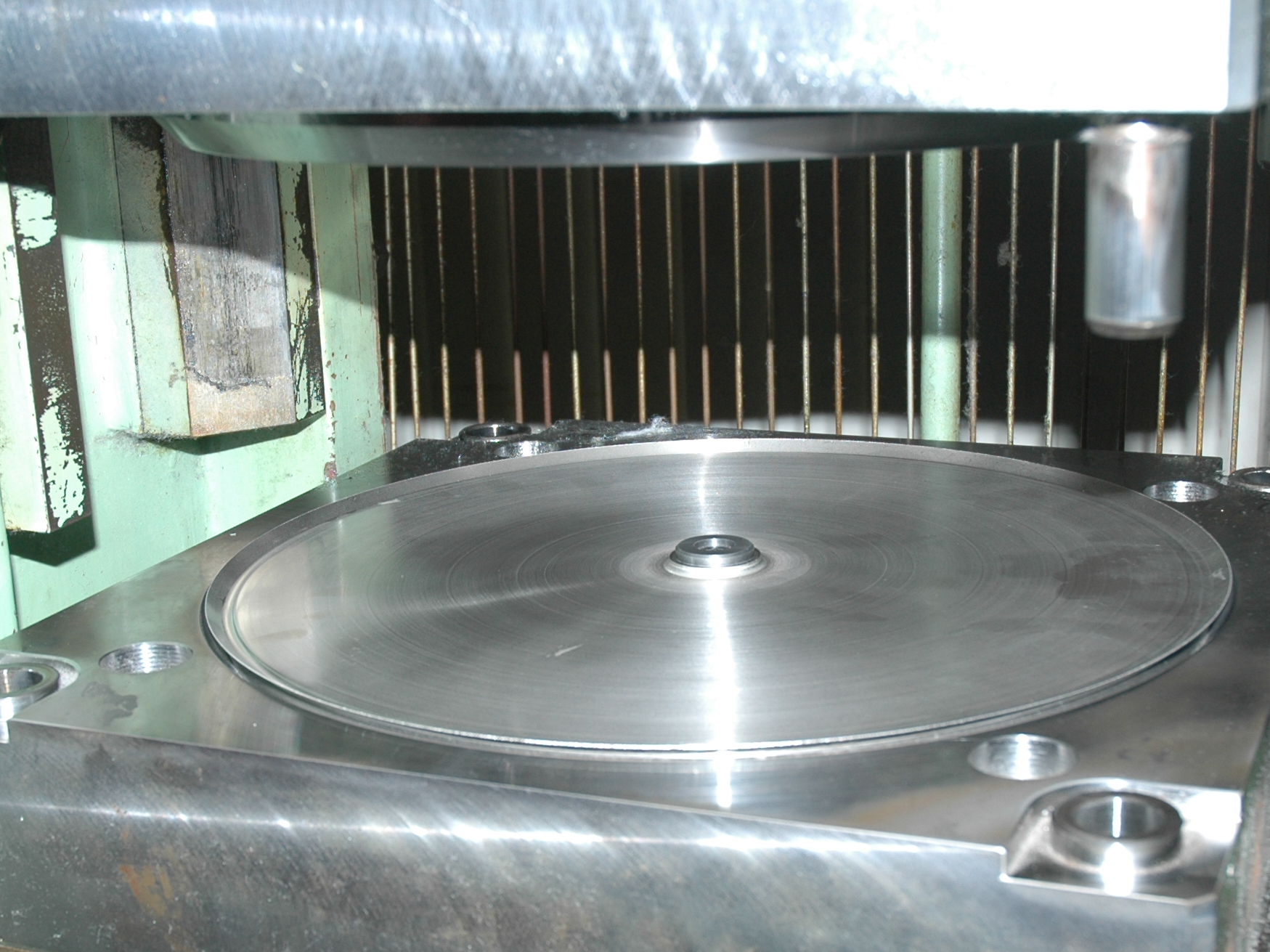

Forming

In order to firmly clamp the stamper to the stamping mould and to hold it in place during the pressing process, a special machine shapes the edges of the stamper on its periphery and central bore. This final step is carried out on a dedicated press which, under pressure, forms and shapes the edges of the stamper – afterwards, the stamper is ready to be used for vinyl production.