Cutting into lacquers is an older method of mastering for vinyl records, but still has many supporters and fans. This analogue mastering technique is widely accepted and used thanks to bigger number of lacquer cutting lathes available and the tradition of lacquer mastering through the years. Hundreds of various lathes were produced during the golden era of vinyl records between 50's and 80's and many of them are still operable. GZ still owns and uses the VMS-70 - one of the best and most reliable lathes ever manufactured. Moreover, engineers and technicians working in GZ upgraded this lathe in 2011, so now it can fully use advantages of the new Vinyl Visual Mastering system.

Cutting into lacquers is an older method of mastering for vinyl records, but still has many supporters and fans. This analogue mastering technique is widely accepted and used thanks to bigger number of lacquer cutting lathes available and the tradition of lacquer mastering through the years. Hundreds of various lathes were produced during the golden era of vinyl records between 50's and 80's and many of them are still operable. GZ still owns and uses the VMS-70 - one of the best and most reliable lathes ever manufactured. Moreover, engineers and technicians working in GZ upgraded this lathe in 2011, so now it can fully use advantages of the new Vinyl Visual Mastering system.

The principle of lacquer technology

The audio signal is transcribed into a master plate called lacquer through a dedicated cutting head comprised of two moving coils perpendicular to each other - one for the left and one for the right channel. Movements of both coils are transfered to a cutting stylus with a sharp triangular tip on the end. The stylus for cutting into soft lacquer is heated and is made out of saphire or ruby gems and cuts a spiral V-shaped sound groove into a nitrocelulose layer covered on an aluminium disc. Stampers for record pressing are manufactured from such mastered lacquers by a three step electroforming process in electrolytic baths. It is recommended to start these processes with already cut lacquers as soon as possible to avoid deformations of grooves caused by heat and other environmental factors.

The audio signal is transcribed into a master plate called lacquer through a dedicated cutting head comprised of two moving coils perpendicular to each other - one for the left and one for the right channel. Movements of both coils are transfered to a cutting stylus with a sharp triangular tip on the end. The stylus for cutting into soft lacquer is heated and is made out of saphire or ruby gems and cuts a spiral V-shaped sound groove into a nitrocelulose layer covered on an aluminium disc. Stampers for record pressing are manufactured from such mastered lacquers by a three step electroforming process in electrolytic baths. It is recommended to start these processes with already cut lacquers as soon as possible to avoid deformations of grooves caused by heat and other environmental factors.

Advantages of lacquer cutting

Thicker lacquer layer allows:

a) bigger vertical amplitudes which can carry more out-of-phase low frequency signals (e.g. a bass quitar or a kick drum placed only in one channel), but with higher risk of mis-tracking

b) wider and deeper grooves which are more tolerant for most kinds of surface damage and offer a little bit higher resistance for skipping caused by badly calibrated turntables. With very wide and deep grooves, more troubles can raise in the following galvanic and pressing processes. It often results in higher noise and more crackles and pops. See FAQ.

The softer lacquer material allows very high cutting levels resulting in very loud records, but with risk of various distortions and mistracking on some turntables.

Lacquer mastering is more suitable for loud and shorter recordings, esp. for DJ records, dance genres and scratching.

Lacquer mastering studio

-

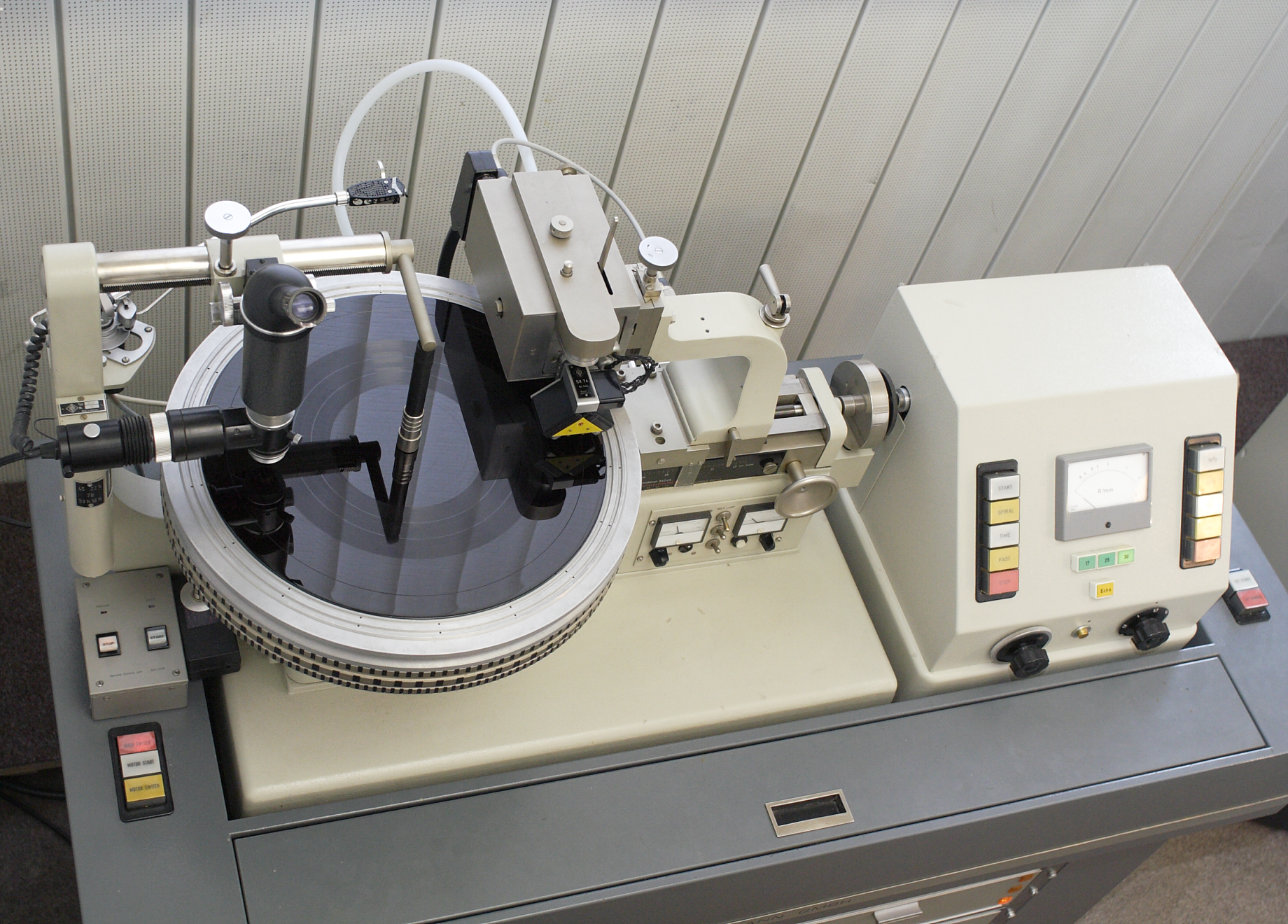

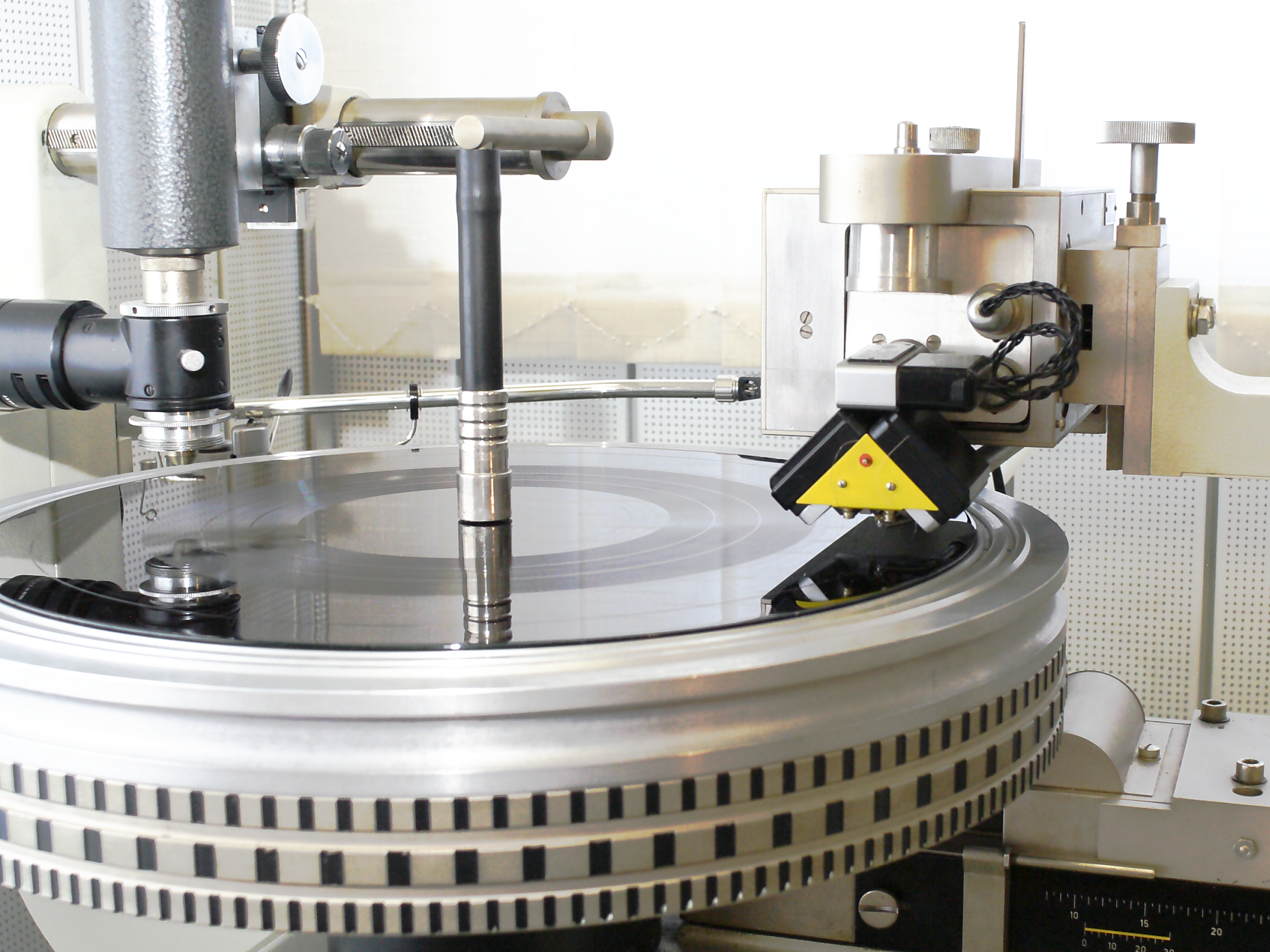

Neumann VMS-70 cutting lathe upgraded for VVM

Neumann VMS-70 cutting lathe upgraded for VVM

-

Neumann SAL-74 modified amplifiers

-

Neumann SX-74 cutting head

-

GZ made control console for the VVM workstation and with VU meters and a NTP meter module

-

JBL 4343 studio monitor system

-

Top quality PrismSound Orpheus audio interface for DA/AD conversions

-

Technics SL-1210 MK2 direct drive turntable for playback test pressings